VAST is More Profitable

VAST turbines are 20% more efficient and have lower CapEx/OpEx delivering increased profitability.

Why is VAST More Profitable?

VAST Cycle is More Fuel Efficient

Fuel makes up 60-70% of gas turbine plant operating costs. VAST increases efficiency by 20%, recycles exhaust heat and captures cooling water without additional treatment, driving higher profitability.

VAST Cycle Generates Clean Water

Purifying injected cooling water to boiler quality represents one of the largest costs for wet combustion cycles. VAST does not need to purify additional water because it recycles all the water and adds more than 10% net new water by capturing water formed during combustion. This eliminates the need for constantly adding and purifying water which significantly reduces operating costs and boosts profitability.

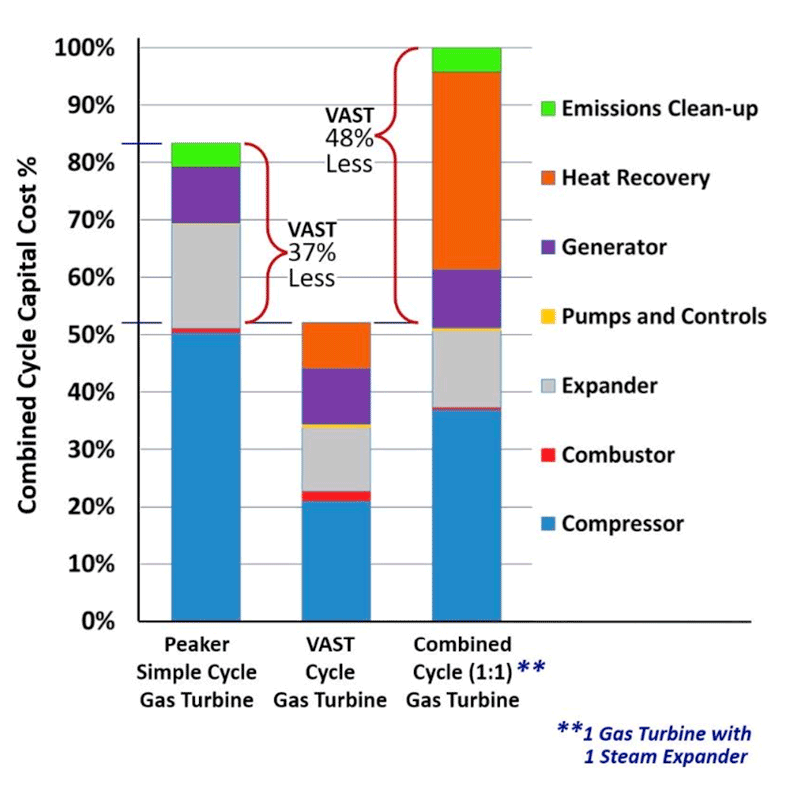

VAST Lowers CapEx

VAST’s compressor accounts for only 30% of the total equipment cost, compared to 60% in a typical gas turbine. Using the patented VAST® Wet Compression™ will further reduce compressor cost and improve efficiency. By reducing the size of the compressor by 70%, VAST further lowers CapEx by ~30%.

VAST lowers CapEx/MW by 37% compared to simple cycle peakers. By eliminating the need for Selective Catalytic Reduction (SCR) VAST reduces CapEx by 7-10%.

VAST uses 48% lower CapEx/MW than a combined cycle because VAST melds the gas turbine + the steam turbine of a combined cycle into one expander turbine in the VAST Power Cycle. VAST substantially eliminates the steam turbine bottoming cycle of the 1 gas turbine +1 steam turbine combined cycle.

VAST requires equipment that costs less to build and maintain. That is a VAST Advantage.

No SCR Required

To meet California’s stringent emission regulations, competitors must use post-combustion exhaust gas treatments such as SCR (Selective Catalytic Reduction). This adds 7-10% in CapEx cost and significant OpEx expense. VAST does not incur those costs because we never create the NOx or CO that need to be removed. VAST’s cleaner combustion enables less expensive cleanup.

VAST Lowers OpEx

VAST precisely and accurately controls combustion and the Turbine Inlet Temperature. This lowers thermal fatigue which reduces maintenance, increases durability, improves availability, and operating uptime. VASTurbines do not subject critical parts of its hot gas path to rapid temperature changes leading to metal fatigue and increased OpEx. These financial benefits, improved durability and availability are VAST Advantages.

VAST Virtually Eliminates Water Purification Expense

The VAST Liquid Recuperator recycles nearly all of the exhaust heat via steam and hot water. It condenses and recovers net water thereby eliminating the critical cost of supplying boiler quality replacement water currently incurred by simple water spray cooling to reduce NOx. Operational simplicity and cost savings are breakthrough VAST Advantages.

VAST Recovers Combustion Generated Water

VAST’s approach recovers the water produced during the combustion of natural gas and other fossil fuels, generally estimated at 12% of the fuel’s mass. This makes VAST particularly advantageous on ships and in desert conditions.

Multi-fuel

The VAST® FastRamp™ Turbine offers ultra-clean NOx and CO emissions with ~19% less CO2, when combusting natural gas, than today’s best simple gas turbine peakers. As Alternative Fuels such as hydrogen, ammonia or methanol become available, the VAST FastRamp Turbine can switch to using those fuels. This multi-fuel capability increases availability and can reduce fuel costs.

Why is VAST More Profitable?

Cleaner + More Efficient + Less CapEx/OpEx + Faster Ramping = More Profitable

Contact US

If you would like to learn more about VAST technologies and the VAST systems for supporting renewable power grids, please reach out to us.

Who is VAST ?

The VAST team is made up of experts from varied markets who enable us to meet the right needs with the right partners.